RTO(Regenerative Thermal Oxidizer)

Keywords:

Category:

Product Description

It mainly includes regenerator (inside the regenerator), oxidation chamber, inlet and outlet air switch valve, smoke exhaust system, connection pipe, etc., the equipment is safe and reliable, simple operation, easy maintenance, low operating cost, high VOCs removal rate.

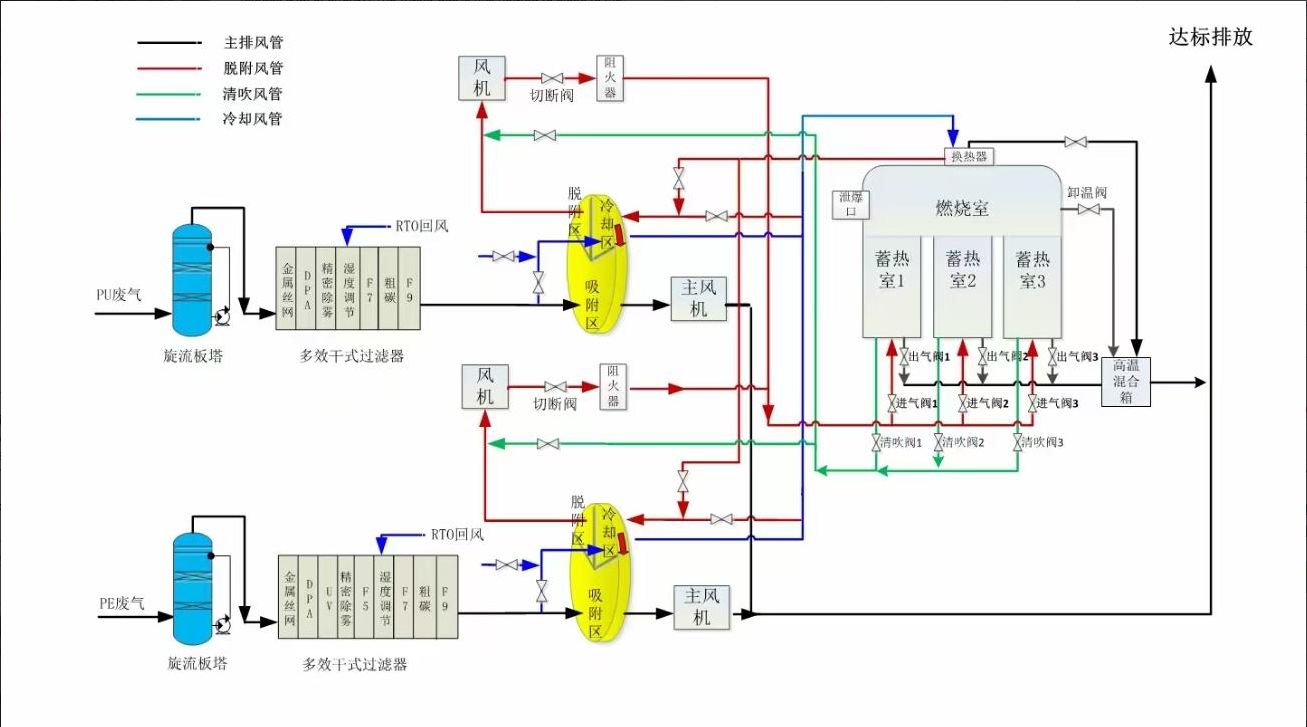

1、The working principle of RTO

Combustible organic waste gas at 760~1000℃ thermal oxidation reaction, production of CO2 and H2O and other products and release a lot of energy. The waste gas is first heated to close to the thermal oxidation temperature through the ceramic heat accumulator,and then enters the combustion chamber for thermal oxidation, and the temperature of the oxidized gas rises, and the organic matter is basically converted into CO2 and H2O. The purified gas passes through another heat accumulator, the temperature drops, and the gas is discharged after reaching the national emission standard.

2、The principle of exchange heat in RTO ceramic heat accumulator

The regenerative thermal oxidizer (RTO) device features a regenerative ceramic-filled bed heat exchanger that maximizes heat recovery, with a efficiency.with a heat recovery rate exceeding 95%, without or with minimal fuel consumption when processing VOCs.

The heat exchange principle of the device is to pass the oxidized hightemperature gas through a special ceramic regenerator, which heats the ceramic body and "stores heat" for subsequent preheating of organic waste gases. This saves fuel consumption for heating the waste gases. The ceramic heat storage chamber should be divided into two or more chambers (including two), and each heat storage chamber should go through the processes of heat storage, heat release, and cleaning in sequence and continuously. After the heat exchanger releases heat, it should immediately introduce an appropriate amount of clean air to clean the heat exchanger (to ensure that the VOC removal rate is above 98%), and the cleaning process should be completed before starting the "heat storage" process. Otherwise, the residual VOCs will be discharged into the chimney with the flue gas, reducing the treatment efficiency.

3、The safety pretreatment of RTO

Due to the fact that RTO units often use open flames for operation, the following safety precautions should be taken before use:

(1) Concentration control: For safety reasons, the concentration of VOCs in the exhaust gas should usually be controlled below 25% LEL to prevent explosions or fires;

(2) Backfire control: To prevent backfire, the minimum flow rate of the exhaust gas should always be greater than the backfire speed when designing the pipe size, and an appropriate safety factor should be selected;

(3) Safety measures: Safety control measures such as installing Venturi flame arresters, backfire preventers, safety liquid seals, air dilution, and non-backfire injection can be taken;

(4) Alarm and linkage: An explosion or backfire alarm and a safety interlock control system should be installed.

4、The advantage of RTO

(1) It can almost handle all organic compounds in waste gas.

(2) It can adapt to the composition and concentration changes and fluctuations of VOCs in waste gas.

(3) It is not sensitive to the presence of a small amount of dust and solid particles in waste gas.

(4) It has the highest thermal efficiency among all thermal combustion purification methods (>90%).

(5) It can achieve self-heating operation without additional auxiliary combustion under suitable waste gas concentration conditions.

(6) It has high purification efficiency and low maintenance workload, and operation is safe and reliable.

(7) Organic deposits can be periodically removed, and the heat storage body can be replaced.

(8) The pressure loss of the entire device is small (the total pressure loss of the RTO system is generally <3000 pa, varying with the structural type of the heat storage body and gas velocity), and the service life of the device is long

Related Products

Product Inquiry

If you are interested in our products, please contact us immediately and the company will arrange for a professional to respond to your questions.

Tiansheng Environmental Protection Equipment

Contact Person: Manager Liu

Tel: +86-18663781444

WhatsApp: +86-18660773816

Address: Diaozhen Industrial Park, Zhangqiu District, Jinan City

Copyright © 2023 Jinan Tiansheng Environmental Protection Equipment Co., Ltd.