Zeolite runner adsorption technology

Keywords:

Category:

Product Description

Zeolite is a natural or artificial aluminum silicate mineral with a unique pore structure and adsorption properties. In zeolite rotor, zeolite molecular sieve is attached to the substrate to form a certain thickness of molecular sieve layer. When the exhaust gas passes through the zeolite rotor, the organic components in the exhaust gas are adsorbed by the molecular sieve, thus achieving purification. When the molecular sieve is saturated, it is regenerated at high temperature to restore its adsorption capacity.

The working principle of zeolite rotor:

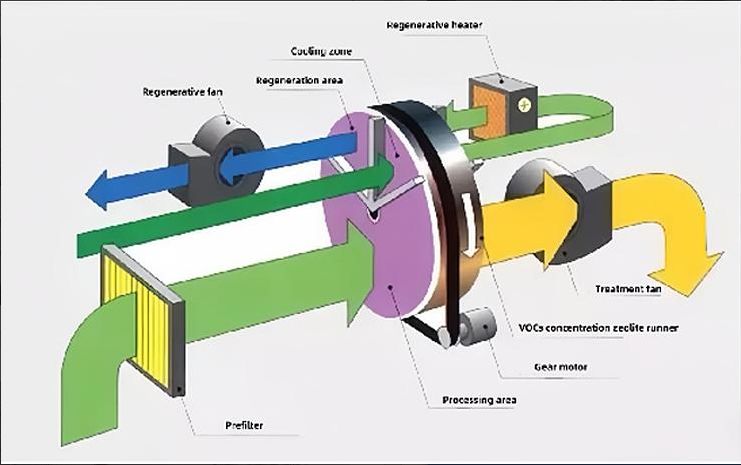

The zeolite rotor process adopts the principle of adsorption concentration, which consists of three treatment steps: treatment, desorption, and cooling. The VOC-containing waste gas first passes through a filtration device, then enters the treatment area of the zeolite rotor, where the VOCs are adsorbed by the zeolite rotor adsorbent. The treated gas is discharged in the treatment area, while a

part of the VOCs is adsorbed on the zeolite rotor. Then, in the regeneration area, the VOCs are desorbed and concentrated by hot air treatment. The zeolite rotor is cooled in the cooling area, and the cooled air is then heated again and used as regeneration air to achieve energy- saving effects.The zeolite rotor concentration equipment is suitable for large wind volume and low concentration places, mainly composed of exhaust gas pretreatment system, molecular sieve rotor adsorption concentration system, desorption system, cooling and drying system, and automatic control system, etc, There is usually a post-treatment system after the rotor, the common process is zeolite rotor + RCO. zeolite rotor + RTO.

Related Products

Product Inquiry

If you are interested in our products, please contact us immediately and the company will arrange for a professional to respond to your questions.

Tiansheng Environmental Protection Equipment

Contact Person: Manager Liu

Tel: +86-18663781444

WhatsApp: +86-18660773816

Address: Diaozhen Industrial Park, Zhangqiu District, Jinan City

Copyright © 2023 Jinan Tiansheng Environmental Protection Equipment Co., Ltd.